Constructed with the financial support of SNSF, Société Académique de Genève, Fondation Ernst et Lucie Schmidheiny, Fondation Ernest Boninchi and the University of Geneva.

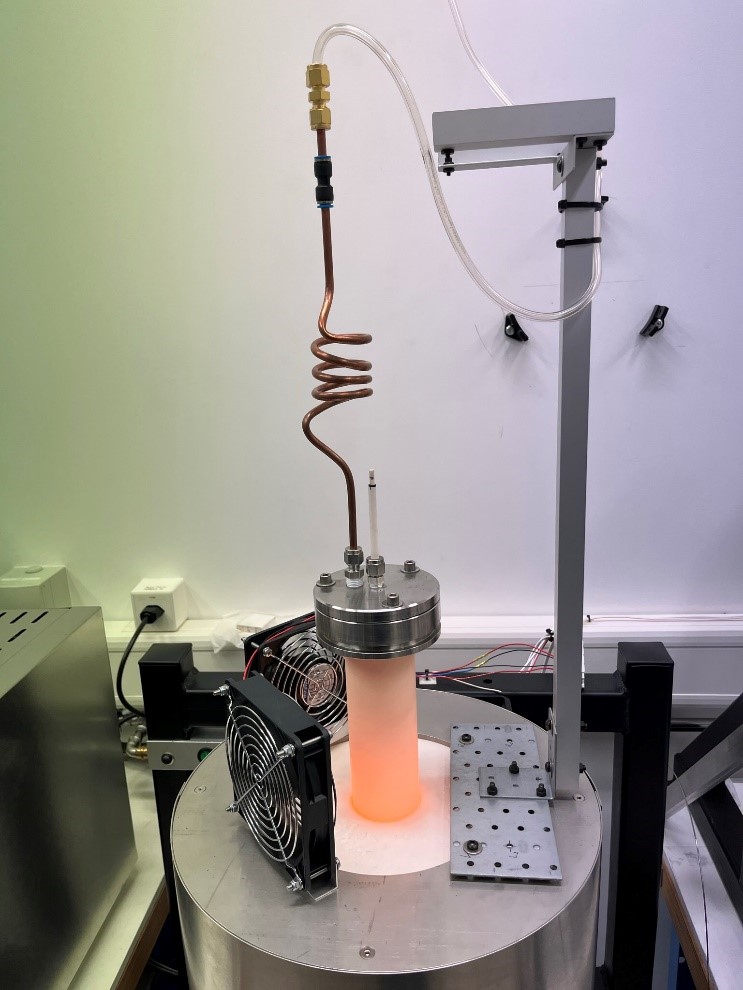

This apparatus is used to conduct experiments at atmospheric pressure at precisely controlled redox conditions up to a temperature of 1550 oC.

Performance Highlights:

- Spiral-cut tubular high-density SiC heating element with 30 cm-long heated zone, which allows long-duration experiments at temperatures up to 1550 oC

- 6 cm long hot zone with temperature uniformity better than 5 oC

- 51 mm inner diameter furnace tube

- Redox control by using CO – CO2 gas mixture

- 0-20, 0-500, 0-1000 ml/min mass flow controllers with 0.5% full scale accuracy and 0.15% precision to facilitate precise and accurate redox control over a broad fO2 range

- Air-cooled end caps

- Mechanical alumina rod assembly that allows dropping the experimental load directly into water bath under the furnace for rapid quenching

- The furnace can be turned off between experiments