Purchased with the support of SNSF, Société Académique de Genève, Fondation Ernst et Lucie Schmidheiny, Fondation Ernest Boninchi and the University of Geneva.

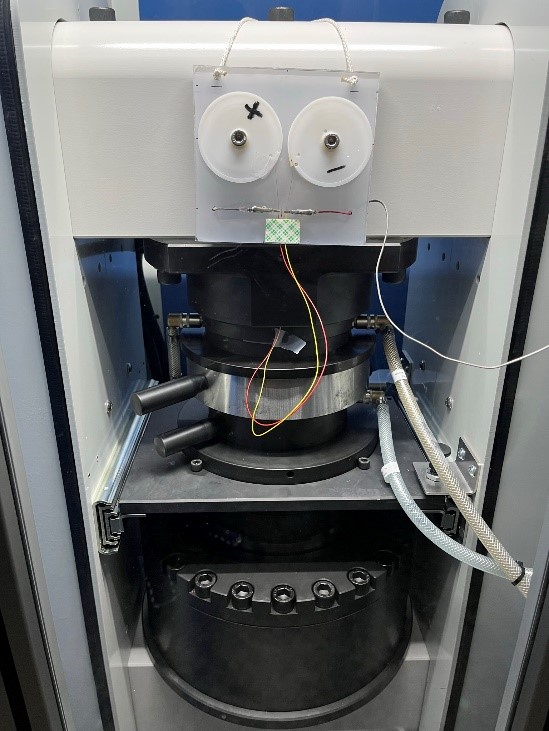

We use this apparatus to attain P-T conditions typical of the Earth’s middle and lower crust and upper mantle.

This is an end-loaded piston cylinder apparatus, which was designed and built by Strecon AS in Denmark upon consultation of the principal features with us. It is a powerful yet lightweight apparatus. Its frame is made of strip-wound pre-stressed steel leading to volume and weight reduction and enhanced strength. It uses a twin hydraulic RAM wherein the process RAM is basically the piston of the end load RAM. The pressure stack can be removed from the frame on a sliding plate for easy assembly. Both the end load and process RAM oil pressures are generated and maintained by compressed air-driven liquid pumps. The pressure vessels are also made of strip-wound steel rings around a tungsten carbide core, and were designed for long lifetime at the high end of the allowable pressure range.

Performance Highlights:

- Max. 320 tons of end load and 90 tons of process load

- Equipped with 14 mm and 19.05 mm (3/4”)-bore pressure vessels

- Maximum routinely attainable pressure at 3.5 and 2 GPa with the 14 and 19 mm diameter assemblies, respectively.

- Temperatures up to 1600 oC controlled by sophisticated Eurotherm EPC3004 temperature controller

- Accurate and precise monitoring of the process pressure by a digital pressure transducer

- Convenient automatic repositioning of the piston into the lowermost position by using compressed air

- Easy access for building the pressure stack

- Thermocouple insertion from the top

- Polycarbonate safety shielding with interlock to hydraulic pumps

- Equipped with B or S-type thermocouples

- Accessories available for the manufacturing of salt cells and ceramic assembly parts (e.g. Magnorite, boron nitride)

- The complete apparatus has a 70 X 140 cm footprint and weight of 1170 kg.