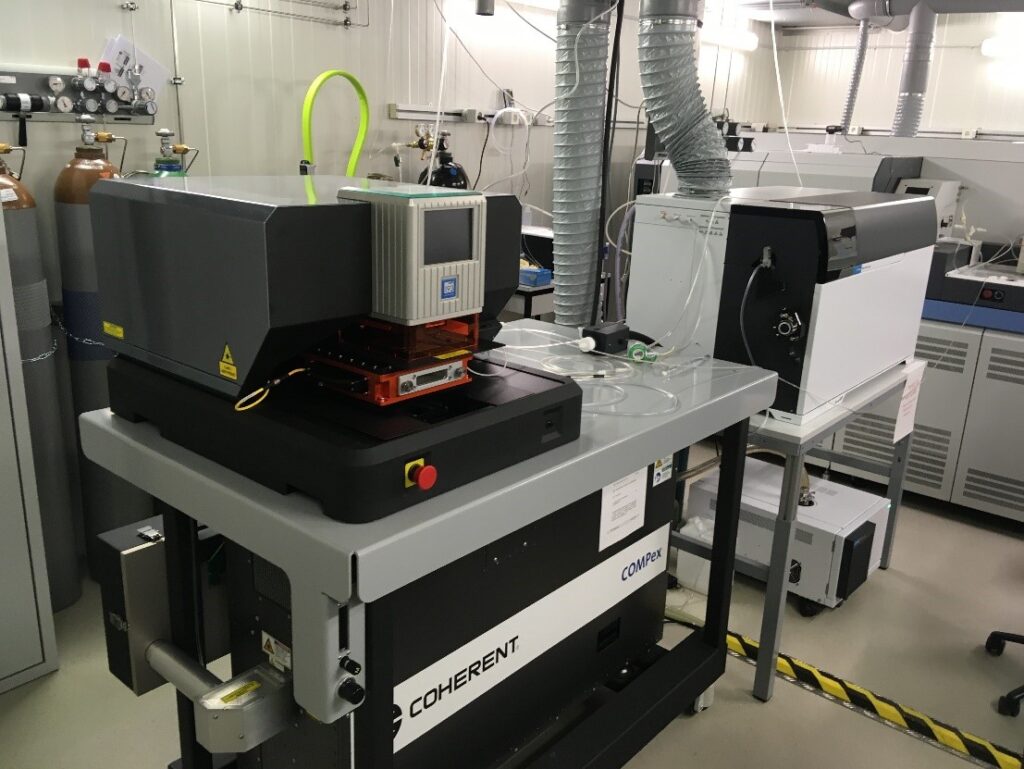

Laser Ablation ICP-MS Laboratory

Purchased with the support of SNSF, Société Académique de Genève, Fondation Ernst et Lucie Schmidheiny, Fondation Ernest Boninchi and the University of Geneva.

The LA-ICP-MS consists of an ESL (former NWR) 193 HE laser ablation system coupled with an Agilent 8900 triple quadrupole ICP-MS. Its configuration has been optimized for the analysis of silicate melt and fluid inclusions in minerals, but it performs equally well in many other typical application areas of LA-ICP-MS.

Performance Highlights:

Laser Ablation System:

- Large format Coherent Compex 102 laser excimer laser source

- Attainable energy densities on sample surface 1 – >50 J/cm2, controlled ablation of quartz and fluorite

- Excellent sample viewing optics – 1-2 µm-sized features are resolvable

- Highly flexible aperture system – circular beam sizes from 1 – 300 µm in single micron steps, freely rotatable rectangular beams with independently variable a and b dimensions in single micron steps

- Two-volume ablation cell with 10 X 10 cm useful area and rapid-flushout, well-adaptable to any sample type/shape

- Sophisticated software: easy orientation by additional wide angle camera or via cross-coordination with imported sample images, programmable patterns, ImageLock feature yields better than 1 µm long-term stage position accuracy, communication plug-in for Agilent ICP-MS (see also www.icpmslasers.com)

ICP-MS:

- Very high sensitivities, 20 – 25 kcps/ppm on mid and heavy masses on NIST610 glass (while using 40 µm circular beam, 10 Hz, 7 J/cm2 energy density on sample, tuned to ThO/Th < 0.3%, Mass 21/ 42 Ca < 0.3% and U/Th=1.00 – 1.05, in single quad, no gas mode)

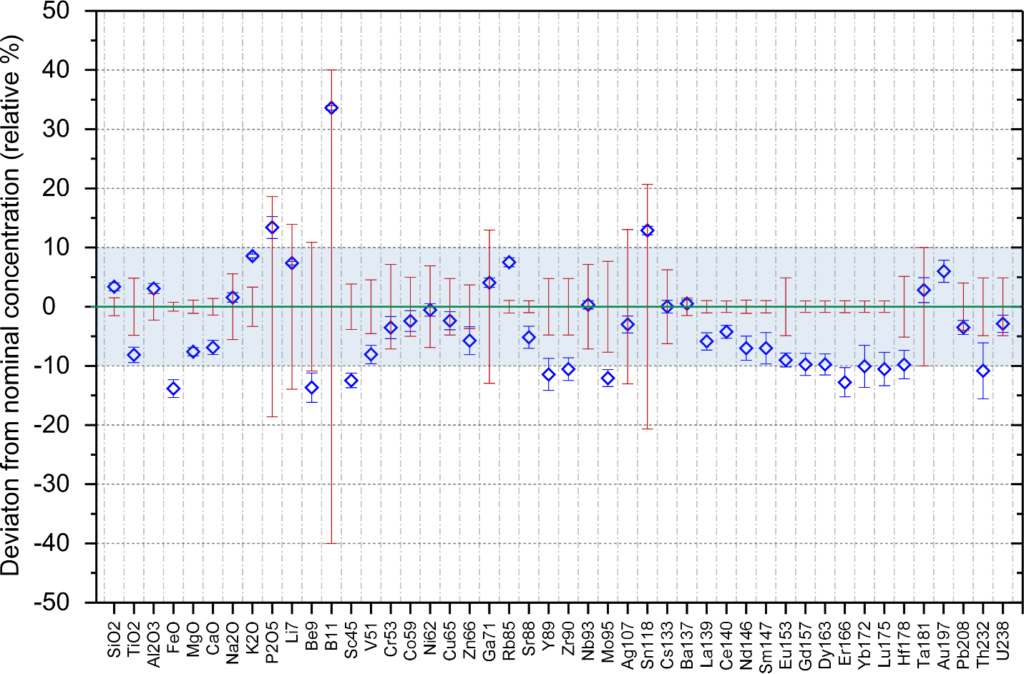

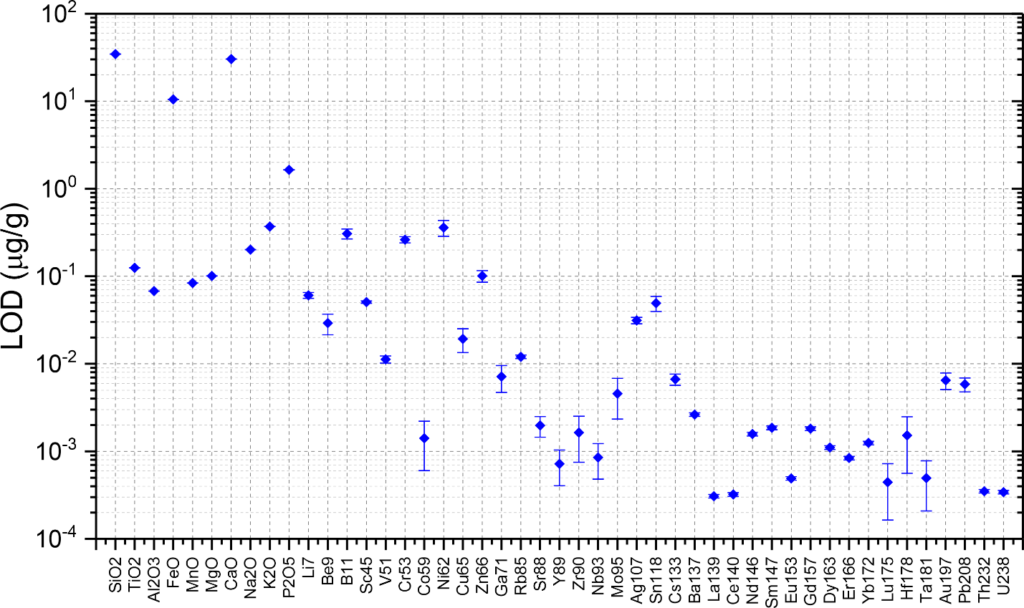

- Practically zero backgrounds on most mid and heavy masses, which coupled with the high sensitivities leads to very low detection limits (see Figure below)

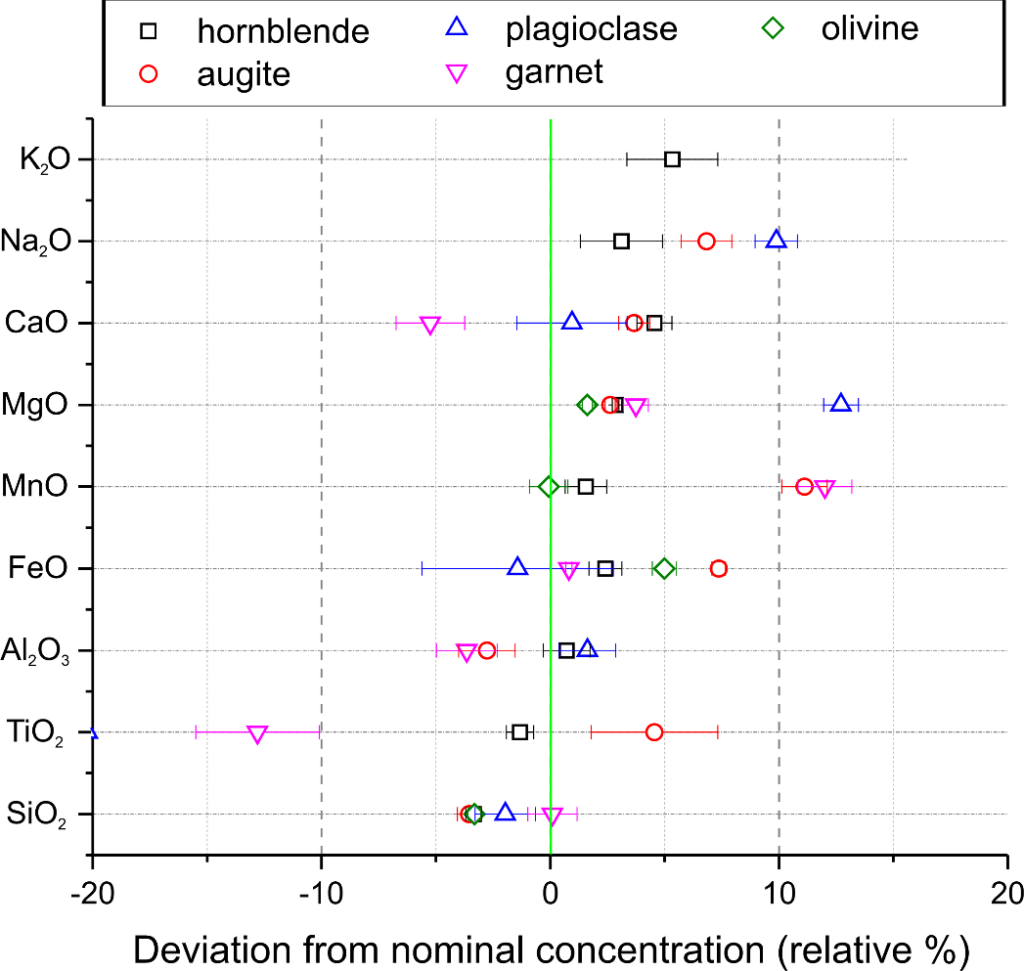

- Being coupled with the excimer laser ablation system, minor matrix dependence of relative sensitivity factors (i.e. largely matrix independent calibration, see Figures below)

- Equipped with 4 collision/reaction gas lines (He, H2, O2, N2O and NH3 gases are available)

- Usage optimized to keep the instrument clean and maintain low detection limits for Au, platinum group elements, S, Cl, Br, I, B and Li.

- Triple quadrupole design facilitates the exploration of new application areas such as in situ Sr isotope ratio analysis even in Rb-rich materials or the analysis of S in the form of oxides to eliminate any oxygen-based interferences (e.g. 16O16O, 18O16O)

Laboratory Environment:

- the instrument is housed in cleanroom environment

- we use 6.0 purity Helium and ultra high-purity gas delivery lines for the lowest gas blanks on volatile elements

- NIST610, NIST612, NIST617, GSE-1g, GSD-1g glasses, an in-house S and halogen doped multielement andesite glass standard, JCP-1-NP and ECRM752-1-NP carbonate pressed nano powder reference materials available

- the instrument shares a room with a Neptune Plus MC-ICP-MS, to which the laser ablation system can also be connected, split-stream application is under development